Research Profiles

Research Projects

Microstructure, Hardness, and Tensile Properties of Additively Manufactured Low-Alloy Steel: A Review

As additive manufacturing (AM) shows great promise in generating functional parts, the list of printable ferrous alloys is growing steadily. Low-alloy steels are such alloys that hold the prospect of being low cost and possessing high strength for structural applications. The AM community is increasingly focusing on examining the properties of such low-alloy steels fabricated using different additive techniques. However, the impact of various printing conditions and heat treatments used after printing on the properties of AM low-alloy steel has not yet been well reviewed. In this review, the microstructure, hardness, and tensile properties of nine different low-alloy steels (4130, 4140, 4340, 5115, 5120, 8620, 8740, 24CrNiMo, Bainidur) have been discussed under different printing parameters and postprinting treatment conditions. In general, the microstructure of additively manufactured low-alloy steels contains martensite, tempered martensite, and bainite with a small percentage of retained austenite. The hardness and tensile strength of AM low-alloy steels are higher than the wrought counterparts. However, the microstructure, hardness, and tensile properties significantly change based on the processing parameters and postprinting heat treatments

Electrochemical behaviour of tungsten nitride thin film in phosphate buffer saline solution for application in bioelectronics

Micro-supercapacitor with tungsten nitride electrode has the potential to be used in bioelectronics for fast power supply. This study examines the electrochemical behaviour of magnetron-sputtered tungsten nitride (W2N) thin film in phosphate buffer saline (PBS) solution to evaluate their corrosion rate as electrodes in micro-supercapacitors used in bioelectronics. The electrochemical behaviour of W2N was analysed using potentiodynamic polarization (PDP) and electrochemical impedance spectroscopy (EIS) techniques. The corrosion rate of W2N was compared with commercially pure titanium (CP-Ti) and magnetron-sputtered pure iron (Fe) film. Our results show that the corrosion current density of W2N was ∼6 times higher than CP-Ti and ∼2.5 times lower than Fe. Additionally, the charge transfer resistance of W2N was 18 times lower than that of CP-Ti and 1.3 times higher than Fe. Overall, the corrosion rate of W2N was significantly higher than CP-Ti and slightly lower than Fe. In summary, the findings suggest that W2N could be a potential candidate for micro-supercapacitor electrodes in bioelectronics. However, further studies are required to fully evaluate the biodegradation behaviour of W2N in vivo.

Enhanced Corrosion Resistance of TiZrN-Coated Additively Manufactured 8620 Low-Alloy Steel in Nitrate Salt Solution and Salt Bath

In this study, corrosion resistance of TiZrN-coated additively manufactured (3D-printed) 8620 steel has been separately studied in a 60–40 wt% NaNO3 + KNO3 molten salt and in an aqueous nitrate salt environment. Microstructural characterization of the as-built bare 3D-printed 8620 sample revealed martensitic microstructures. High-temperature corrosion analysis in molten nitrate salt revealed improved film stability and corrosion resistance of the coating. The coated 3D-printed sample showed no scale of corrosion products, whereas the bare 3D-printed sample exhibited a layer of corrosion products of 2.62 ± 0.24 µm thickness. Potentiodynamic polarization and electrochemical impedance spectroscopy tests in aqueous nitrate salts at room temperature exhibited an ~8-fold decrease in corrosion current density and a ~7-fold increase in charge transfer resistance, indicating enhanced corrosion resistance of the coated 8620. The coated wrought 8620 showed comparable corrosion resistance to that of the coated 3D-printed sample. However, in aqueous solution, the bare 3D-printed sample exhibited localized corrosion, whereas the bare wrought revealed uniform corrosion on the surface.

Improving the Mechanical and Electrochemical Performance of Additively Manufactured 8620 Low Alloy Steel via Boriding

In this study, mechanical and electrochemical performance of borided additively manufactured (AM) and wrought 8620 low alloy steel were investigated and compared to their bare counterparts. The microstructure of borided 8620 exhibited the presence of FeB and Fe2B phases with a saw tooth morphology. Both AM and wrought samples with boride layers showed a similar performance in hardness, wear, potentiodynamic polarization (PD), electrochemical impedance spectroscopy (EIS), and linear polarization resistance (LPR) experiments. However, borided steels exhibited about an 8-fold increase in Vickers hardness and about a 6-fold enhancement in wear resistance compared to bare ones. Electrochemical experiments of borided specimens (both AM and wrought) in 0.1 M Na2S2O3 + 1 M NH4Cl solution revealed a 3–6-fold lower corrosion current density, about a 6-fold higher charge transfer resistance, and about a 6-fold lower double-layer capacitance, demonstrating an improved corrosion resistance compared to their bare counterparts. Post-corrosion surface analysis revealed the presence of thick sulfide and oxide layers on the bare steels, whereas dispersed corrosion particles were observed on the borided samples. The enhanced wear and electrochemical performance of the borided steels were attributed to the hard FeB/Fe2B layers and the reduced amount of adsorbed sulfur on their surface.

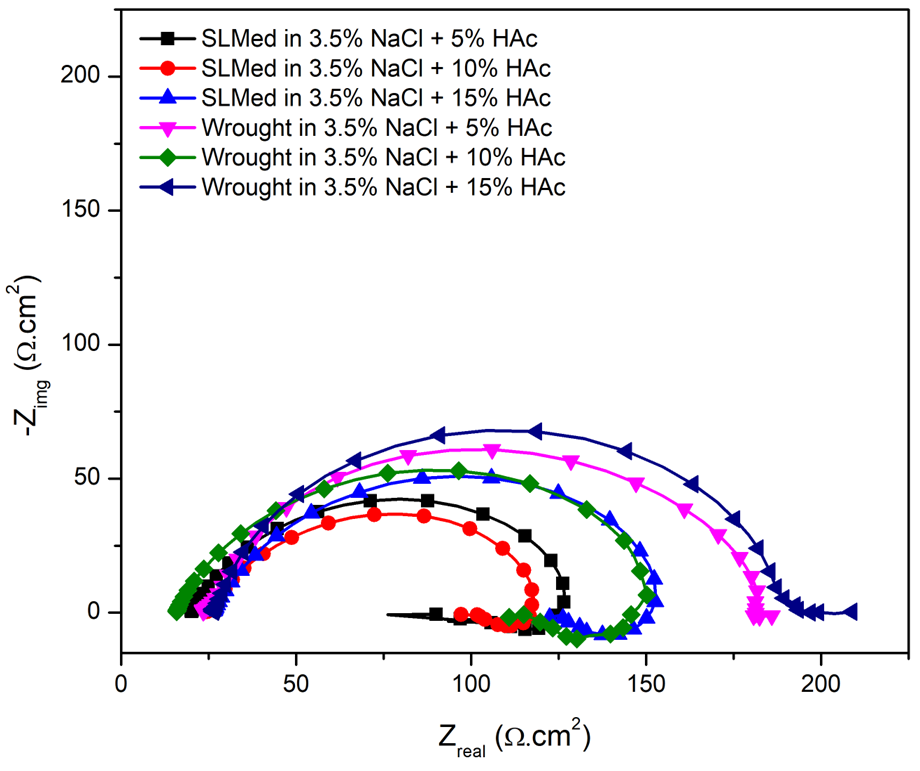

Electrochemical Performance of Additively Manufactured 8620 Low-Alloy Steel: Effect of Acetic Acid

As additive manufacturing is gaining attraction within the scientific community due to its capability to produce functional components, new metal powders are being developed for application in different areas. One such powder is 8620 low alloy steel, which has a wide range of use owing to its hardenability and excellent wear resistance. However, structural components e.g., engine crankshaft, camshaft, wrist pin, etc., made from 8620 steel face material degradation in corrosive environments. In this study, electrochemical performance of additively manufactured and wrought 8620 low alloy steel was investigated via Potentiodynamic Polarization (PD) and Electrochemical Impedance Spectroscopy (EIS) techniques in three concentrations of acetic acid- 5 %, 10%, and 15% in presence of 3.5% NaCl. The understanding obtained from this project can be used to design functional components for the automotive industry.

Publications

Journal Articles

- Sabuz, E.H. and Shabib, I. (2025), Microstructure, Hardness, and Tensile Properties of Additively Manufactured Low-Alloy Steel: A Review. steel research int. 2400421. https://doi.org/10.1002/srin.202400421

- Sabuz, E. H., Maruf, M. A., Haider, W., & Shabib, I. (2024). Electrochemical behaviour of tungsten nitride thin film in phosphate buffer saline solution for application in bioelectronics. Canadian Metallurgical Quarterly, 1–10. https://doi.org/10.1080/00084433.2024.2437848.

- E. H. Sabuz, M. Noor-A-Alam, W. Haider, and I. Shabib, “Improving the Mechanical and Electrochemical Performance of Additively Manufactured 8620 Low Alloy Steel via Boriding,” Corrosion and Materials Degradation, vol. 4, no. 4, pp. 623–643, Nov. 2023, doi.org/10.3390/cmd4040032.

- E. H. Sabuz, M. A. Maruf, W. Haider, and I. Shabib, “Enhanced Corrosion Resistance of TiZrN-Coated Additively Manufactured 8620 Low-Alloy Steel in Nitrate Salt Solution and Salt Bath,” Coatings, vol. 13, no. 12, p. 1998, Nov. 2023, doi.org/10.3390/coatings13121998.

Book Chapter

- E. H. Sabuz and M. Z. Rahman, “Modeling and simulation on additive manufacturing of composite materials,” in Reference Module in Materials Science and Materials Engineering, Elsevier, 2023. doi.org/10.1016/B978-0-323-96020-5.00179-5.

Conference Papers

- E. H. Sabuz, D. Pitts-Reed, W. Haider, and I. Shabib, “Electrochemical Performance of Additively Manufactured 8620 Low-Alloy Steel: Effect of Acetic Acid,” in AIST Steel Properties & Applications Conference Proceedings, Pittsburgh, Philadelphia, Oct. 2022, p.1. doi.org/10.33313/281/003.

- R. E. U. Shougat, E. H. Sabuz, G. M. N. Quader, and M. Mahboob, “Effect of Building Orientation & Post Processing Material on Mechanical Properties of 3D Printed Parts,” presented at the International Conference on Mechanical, Industrial and Energy Engineering 2016, Khulna, Bangladesh, Dec. 2016.

- E. H. Sabuz and S. Islam, “Design and online control of a single channel myoelectric prosthetic arm,” presented at the International Conference on Mechanical, Industrial and Energy Engineering 2016, Khulna, Bangladesh, Dec. 2016.

Pre-Prints

- Ezazul Haque Sabuz. “A brief market analysis of available electric power trains for vocational trucks”. December 05, 2024. DOI: 10.36227/techrxiv.173337325.51455942/v1.

Peer reviewing as reviewer

Journals

- SAE International Journal of Materials and Manufacturing, ISSN: 1946-3979, e-ISSN: 1946-3987 (12 reviews completed)

- SAE Non-Event Technical Papers (13 reviews completed)

- SAE International Journal of Engines (ISSN: 1946-3936, e-ISSN: 1946-3944) (1 review completed)

- SAE International Journal of Electrified Vehicles , ISSN: 2691-3747, e-ISSN: 2691-3755 (Newly appointed)

- SAE International Journal of Commercial Vehicles, ISSN: 1946-391X, e-ISSN: 1946-3928 (Newly appointed)

- SAE International Journal of Sustainable Transportation, Energy, Environment & Policy, ISSN: 2640-642X, e-ISSN: 2640-6438 (Newly appointed)

- The 3rd IEEE International Conference on Computing and Machine Intelligence (ICMI 2024), Michigan, USA (4 reviews completed)

- IEEE Transportation Electrification Conference & Expo 2024, Illinois, USA (5 reviews completed)