Blog Posts

The communication between an electric vehicle and the charging station is quite interesting. Charging protocols such as ISO 15118 ensure that the charging process is safe. For example, the charging cable we see for EV charging is not energized until it is plugged into an EV and the EV starts charging. The communication between the charging station and the EV happens via the Control Pilot line. Here is a brief summary of the steps that happen during the charging process in Level 1 and Level 2 home chargers.

1. A user takes the charging plug from the home charging station and plugs it into the vehicle port.

2. As soon as the EV is plugged, the charger recognizes the EV. The EV also senses that it is connected to a charging station.

3. The charging station (charger) sends a PWM (Pulse Width Modulation) signal through the Control Pilot (CP) line about the charging capability of the charger. For example, a 20% PWM duty cycle means that the charger can provide 12A of current.

4. The EV accepts and sends a signal to the charger to push energy into the vehicle.

5. The charger closes the contactors and sends electricity to the on-board charger of the EV where it is converted to DC and pushed into the EV battery.

Here is an excellent Udemy course on the Electric Vehicle charging process.

Electric Vehicle Charging- From Theory to Practic

This course also teaches how to make an EV simulator. An EV simulator is a device that tricks the charging station into thinking it is connected to an EV when it is not. Fun to see the charging station getting tricked!

Linkedin post: Click Here

Whoever watched the Marvel movie ‘Infinity War’ knows that Dr. Strange saw 14 million different battle outcomes against Thanos. The Avengers lost every battle except only one. In Engineering terms, this can be called a Failure Mode and Effect Analysis (FMEA). In FMEA, all possible failure modes are analyzed and preventive actions are taken to avoid the failure.

In real life, we are not Dr. Strange and so we can not see the future. But we can reasonably predict the failure modes of a component, the causes and effects of the failure. From there we can take preventive actions to avoid or mitigate the failure. For example, a common failure mode of a hydraulic pump is cavitation and we can take measures to avoid it.

Learning FMEA takes time. I found the AIAG and VDA FMEA handbook (https://lnkd.in/gJjT4U-3) a good source for learning FMEA. Also, this Udemy course (https://lnkd.in/gwh5cKpe) is quite helpful. However, the course could provide a few more examples of FMEA analysis.

FMEA can make Engineers superheroes of engineering problems!

Linkedin post: DFMEA

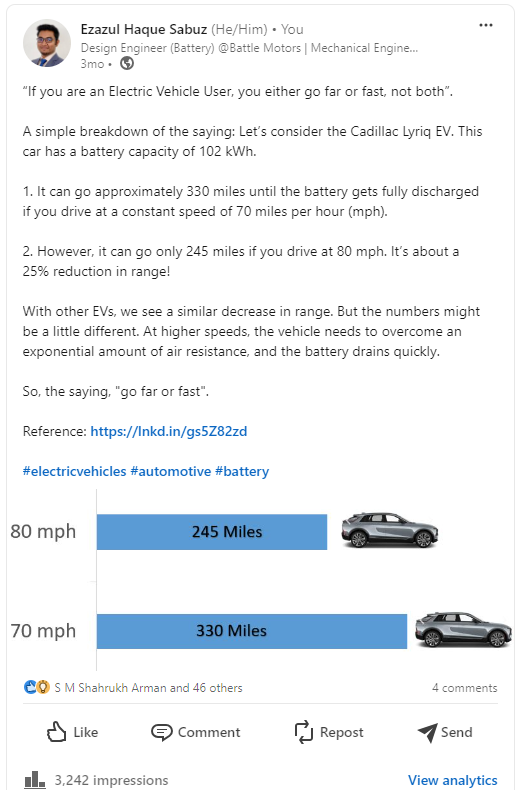

“If you are an Electric Vehicle User, you either go far or fast, not both”.

A simple breakdown of the saying: Let’s consider the Cadillac Lyriq EV. This car has a battery capacity of 102 kWh.

1. It can go approximately 330 miles until the battery gets fully discharged if you drive at a constant speed of 70 miles per hour (mph).

2. However, it can go only 245 miles if you drive at 80 mph. It’s about a 25% reduction in range!

With other EVs, we see a similar decrease in range. But the numbers might be a little different. At higher speeds, the vehicle needs to overcome an exponential amount of air resistance, and the battery drains quickly.

So, the saying, “go far or fast”.

Reference: https://lnkd.in/gs5Z82zd

Linkedin post: EV Range

hashtag#electricvehicles hashtag#automotive hashtag#battery

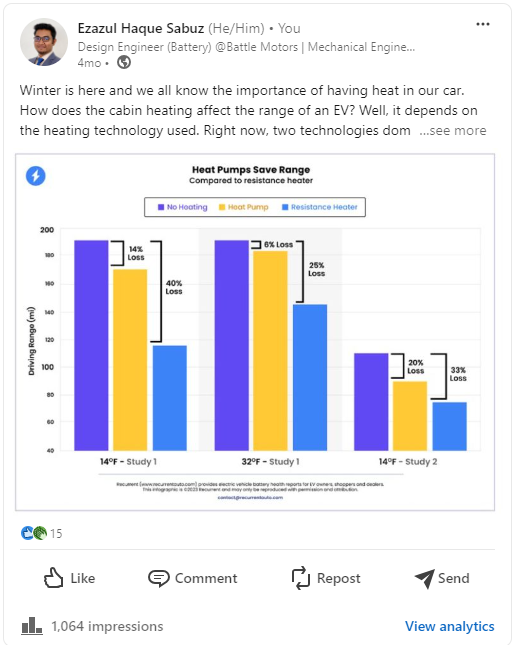

Winter is here and we all know the importance of having heat in our car. How does the cabin heating affect the range of an EV? Well, it depends on the heating technology used. Right now, two technologies dominate the market.

1. PTC heater

2. Heat pump

Since they both require battery power for heating, they both have an impact on an EV’s winter range. But how much? There have been a few interesting studies on this. Here is a comparison:

1. An EV with a PTC heater might lose 33-40% of its range (at 14 degrees F ambient).

2. EVs with a heat pump might lose 14-20% range (at 14 degrees F ambient).

A heat pump is better, right? There is a catch. At lower temperatures, heat pumps are very slow to warm up. So a PTC heater is used for the first few minutes of heating. Thus a combination of both is used in modern cars.

Reference: Heat Pumps: Cold Weather Myth or Worth it? (recurrentauto.com)

Linkedin post: EV cabin heating technology

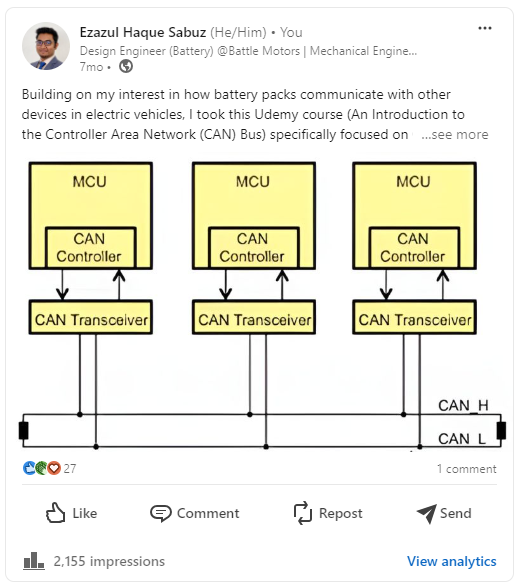

Building on my interest in how battery packs communicate with other devices in electric vehicles, I took this Udemy course (An Introduction to the Controller Area Network (CAN) Bus) specifically focused on CAN. Here are a few key things I’ve learned about CAN communication:

1. Messages from CAN-enabled devices are broadcast to the entire CAN bus, and all devices connected to the bus have access to these messages.

2. Devices are configured to selectively filter and process only the messages that are relevant to their operation based on their individual filter criteria (CAN IDs).

3. Messages in a CAN bus are prioritized, with more important messages getting broadcasted first based on the priority assigned to their CAN IDs.

4. Messages flowing over the CAN bus can be monitored with a CAN bus analyzer.

This course also demonstrated CAN communication between CAN-enabled devices with the CAN learning kit. It was helpful to see the communication happening in practice. Thanks to Emile Ackbarali for this course.

Linkedin post: CAN communcation

hashtag#CAN hashtag#Battery hashtag#EV

I have recently designed a battery coolant tank and learned some interesting things in the process.

– Knowing how to use Solidworks Sheet Metal tool was important for finishing the project successfully. This skill is necessary if you want to work in design and manufacturing.

– Using high-quality parts from well-known suppliers

like McMaster Carr made the design better. Instead of making everything from scratch, you can use the best parts available. Just grab the 3D model and use it in the assembly.

-Making 2D drawings from the model was harder than I

thought. I had to show all the small details like thread sizes, hose types, and welding information. This helped explain how everything fits together.

Designing something is not making everything from scratch, but rather making the best use of what’s available.

Linkedin post: Tank design for battery coolant

hashtag#design hashtag#solidworks hashtag#mechanicalengineering

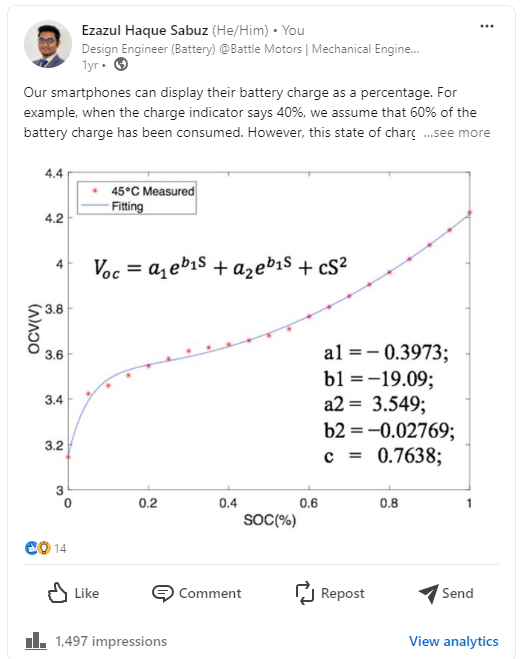

Our smartphones can display their battery charge as a percentage. For example, when the charge indicator says 40%, we assume that 60% of the battery charge has been consumed. However, this state of charge (SOC) can not be directly measured and can only be estimated through quantities, such as battery voltage, current, temperature, etc. One technique is to measure the battery’s voltage as it goes through the charging-discharging cycle and then apply curve fitting with mathematical functions to estimate the SOC.

Ref: A Study on the Open Circuit Voltage and State of Charge Characterization of High Capacity Lithium-Ion Battery Under Different Temperature. Energies 2018, 11, 2408. https://lnkd.in/gWi2FMxX

Linkedin post: Battery SOC calculation algorithm

hashtag#battery hashtag#lithiumionbatteries

The charging time of electric cars is still a deal breaker for many car buyers. Who wants to wait hours to recharge the battery in the middle of a tour? However, all chargers for Battery Electric Vehicles (BEV) are not the same. Based on the amount of power supplied to the battery, there are three levels of chargers.

At level 1, a 120V AC household outlet with a typical output of 1.3kW to 2.4kW is directly connected to the onboard charger (located within the vehicle). The onboard charger itself does the AC to DC conversion. Since it takes a long time to go from completely empty to fully charged, this kind of charger is mainly useful for overnight charging. For instance, using a Level 1 charger to completely charge a Tesla Model 3 might take over 20 hours.

Level 2 charging is approximately 5 times faster than level 1 charging and has an average power output range of 6.2 kW to 19.2 kW. With this charger, a Tesla Model 3 can be fully charged in 8–12 hours. However, installing a level 2 charger (240 V) at home will be an additional expense for homeowners. Public level 2 charging outlets are also available. The onboard charger converts AC to DC, just like it does for level 1 charging.

Level 3 is the fastest level of charging which provides a power output starting from around 50 kW. A tesla model 3 can be charged from 20% to 80% within 30 minutes. AC to DC conversion happens in the charging station, not in the onboard charger. This kind of charging station is not suitable for installation at home.

Charging technology is evolving with time and we can hope to charge our EV in 5-10 minutes in the future maybe?

Linkedin post: Level of EV charging

hashtag#electricvehicles hashtag#charger hashtag#battery

You might have heard of news of smartphone batteries catching fire. Fire in smartphone battery, which is mainly lithium-ion battery, is not uncommon. The same issues can occur with electric car batteries as well. Because of this, electric car batteries are put through extensive testing to assure their safety from fire occurrences as well as a variety of other incidents. Manufacturers of batteries ensure them through well-recognized certification.

>IEC-62133 certification ensures that battery cells are safe to use. This entails tests like forced discharge, shock, vibration, heating, and exposure to fire, among other tests.

> Battery shipping is safe thanks to UN 38.3 certification. Eight tests in total—external short circuit, abnormal charging, forced discharge, impact, shock, vibration, temperature cycling, altitude simulation, and drop test—are carried out to grant this certification. All of these tests are performed at the battery/pack level, not the cell level.

>SAE-J2929 certification assures that a battery system can safely be integrated into an electric or hybrid vehicle.

In addition to these certifications, others like ISO-26262, UL-1998, and IEC-61508 are needed to ensure the reliability of the electronics and related software that control the battery pack. As time goes by, lithium-ion batteries will be safer to use in electric vehicles.

Linkedin post: Battery certification

hashtag#batteries hashtag#electricvehicles hashtag#safety